How do our facilities produce vitamins?

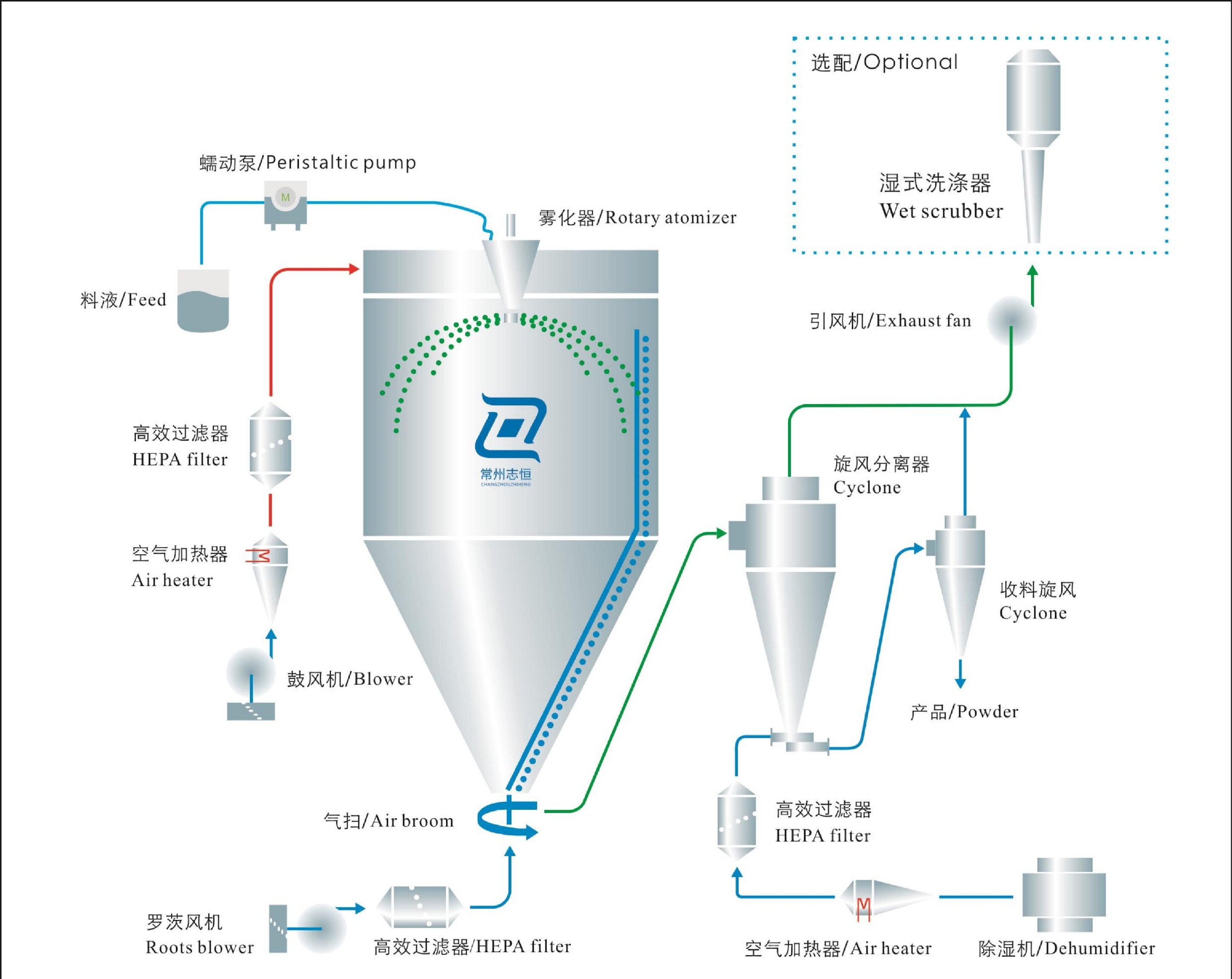

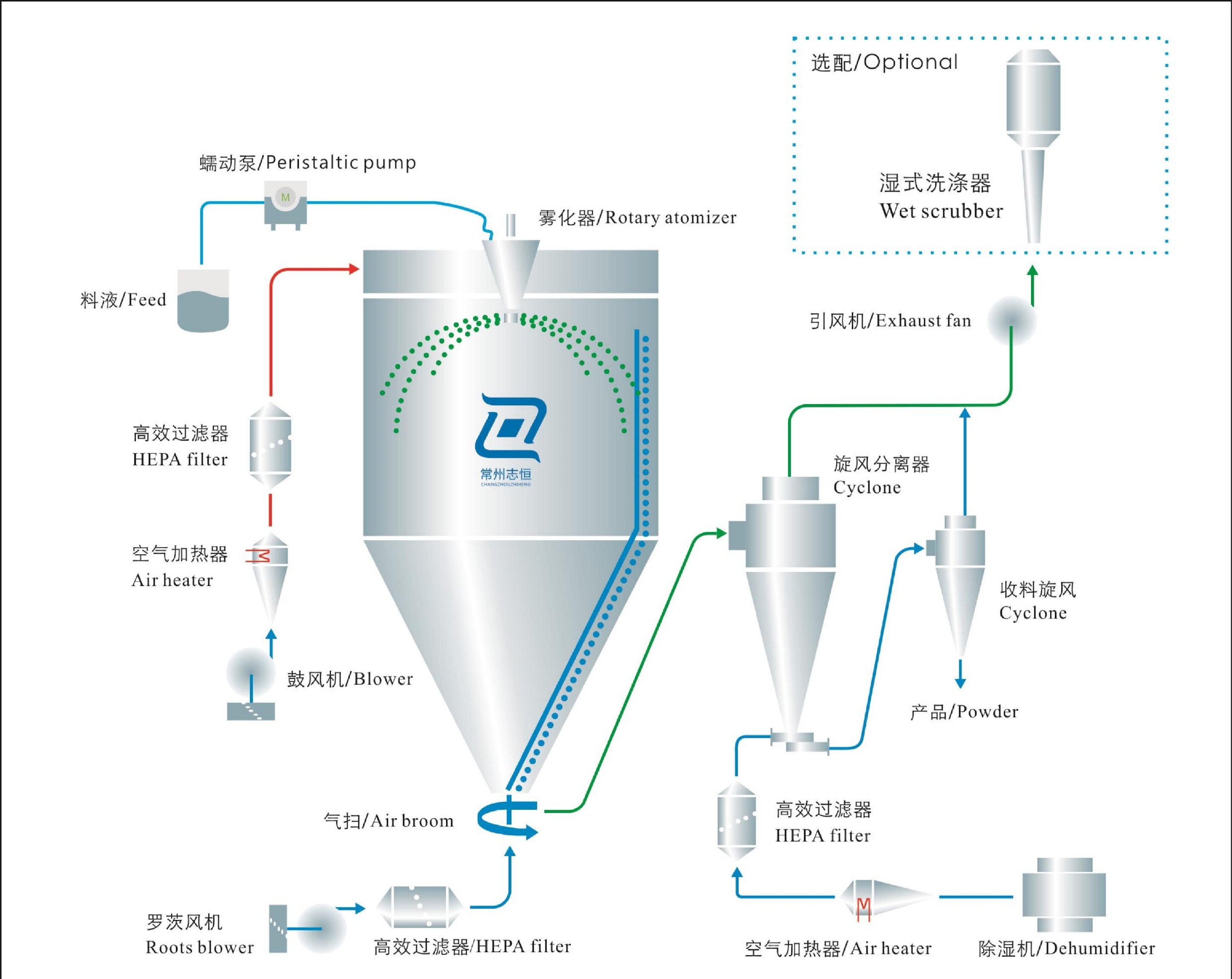

Process flow chart

Advantages of Zhiheng Equipment

There are many vitamin products on the market now. Different vitamins have different properties, but most of them have one common feature, which is "fear of heat". Improper storage may affect the efficacy. At the same time, vitamins have certain standards for the preparation environment. Zhiheng has different ways to deal with different types of vitamins.

Special design of drying chamber to reduce wall sticking

In view of the characteristics that water-soluble vitamins easily absorb moisture in the gas, combine with moisture, and are difficult to further dry, the drying chamber of our equipment adopts a large diameter design, which can effectively reduce the proportion of fog groups contacting the inner wall.

At the same time, the drying chamber of the equipment is also equipped with an air sweeping device, which cooperates with the large diameter design to further eliminate or reduce the wall sticking phenomenon.

Cooling system to reduce material coking

In view of the fact that vitamins are easy to decompose in high temperature environments, the inner wall and tower top of our drying chamber are designed as air cooling jackets. This design can reduce the temperature of the inner wall and avoid the material from coking and deteriorating due to contact with the high-temperature wall surface, which greatly reduces the waste of materials and increases the success rate of drying.

Powder collection system to avoid material agglomeration

After drying, our powder collection system will use dehumidified air cooling technology, which can cool the vitamins and prevent the materials from absorbing moisture, agglomerating and spoiling.

Air filtration meets requirements

Considering the purity of vitamins, all air intake nodes of our equipment strictly use H13 filtration level, which meets GMP production requirements.

Product development and testing equipment

Zhiheng provides customers with laboratory testing equipment for product property configuration, process development and inspection. Whether your product is still in the early stages of research and development or is ready to enter the final process essence stage, our testing facilities and experts can provide you with unparalleled equipment and technical solutions.