Process flow chart

Zhiheng equipment advantage

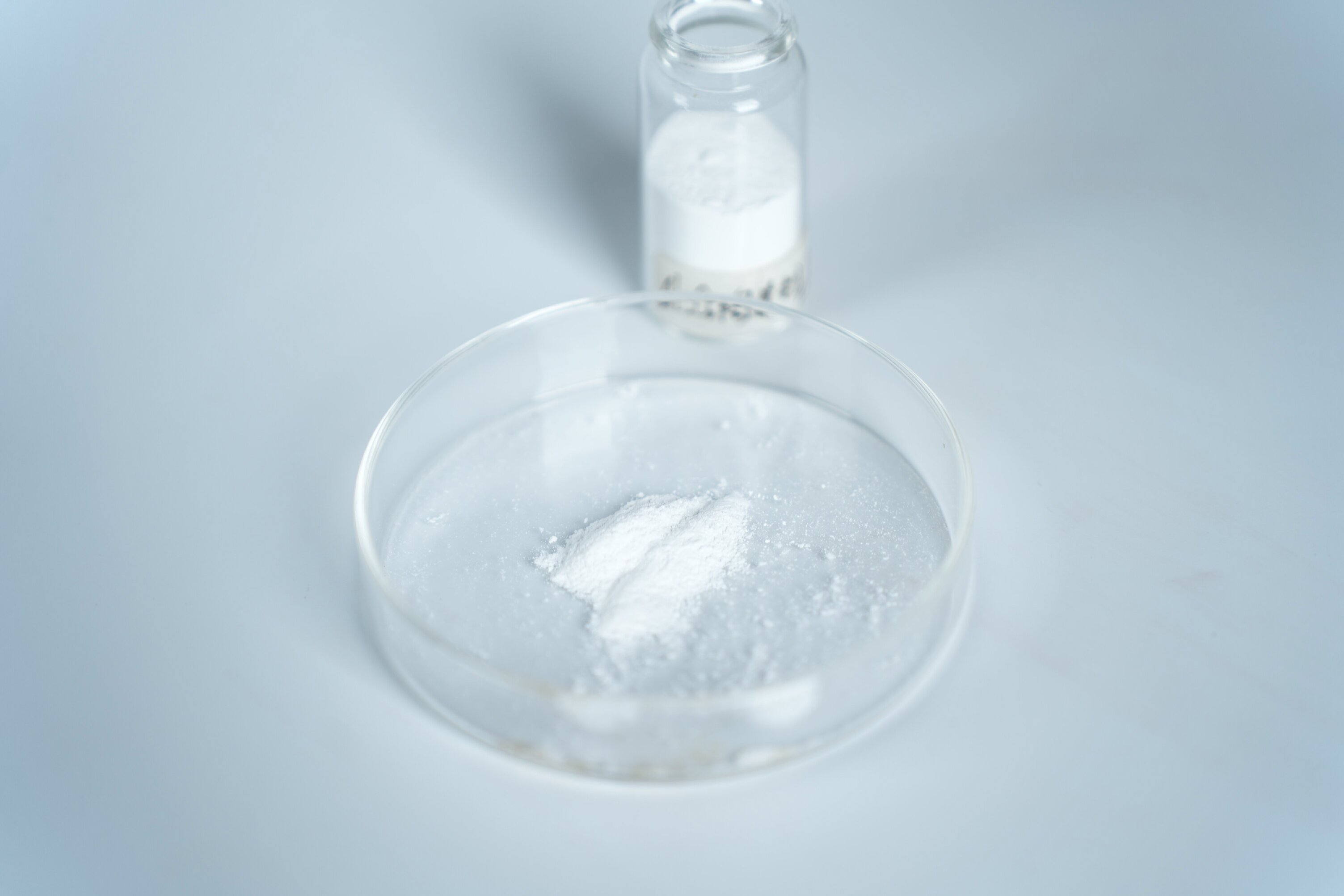

A new type of ceramic atomizing disk is adopted to round the particles

Our spray dryer uses a new type of ceramic atomizing disc to obtain a spherical, round and better flowing powder. The particle size is evenly distributed and the powder size is adjustable.

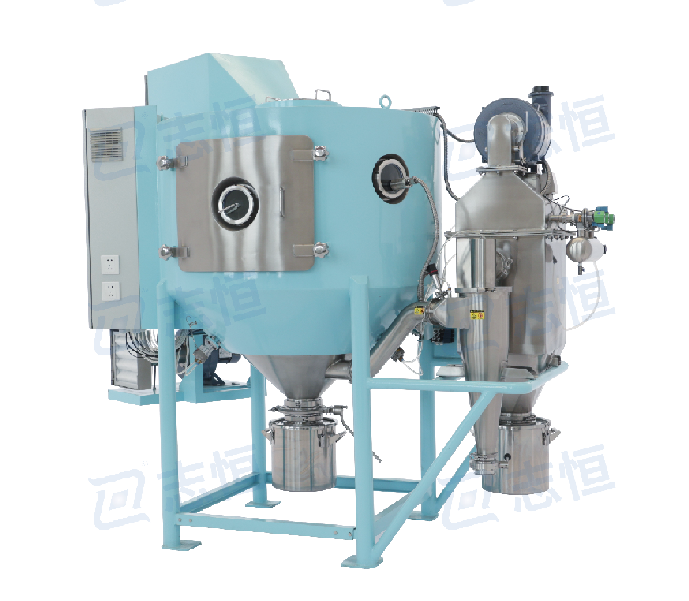

Large aspect ratio design to avoid powder sticking to the wall

The equipment tower is designed with a large cone Angle and a small aspect ratio, which reduces the height of the traditional spray engine by 50%. This design can reduce the wall adhesion phenomenon of the material powder. At the same time, the main drying room of the equipment adopts the R-angle arc transition manufacturing process, which avoids the accumulation of powder residue and increases the recovery rate of materials.

Special collection and filtration methods to improve the recovery rate

The specially designed low cap collection method can maximize the wind to select particles and effectively improve the recovery rate of pelletizing products. The folding drum bag filter greatly improves the dust removal filter area, improves the recovery rate of fine powder, and the discharge grade can be up to 10mg/m³.

Triple-effect filtration to ensure clean materials

The inlet air is filtered through the junior high and junior high efficiency, and the filtration grade reaches the H13 standard of the pharmaceutical industry, ensuring the cleanliness of the prepared materials and providing qualified particles for the post-process such as molding and sintering.

Product development test equipment

Zhiheng provides customers with laboratory testing equipment, which can carry out product property configuration, process development and inspection. Whether your product is still in the early stages of development or ready to enter the final stage of process excellence, our testing facilities and experts can provide you with unmatched equipment and technical solutions.