Product Application丨Application of microcapsules in spray drying!

Information sources:本站 | Release date:

2023-12-01

| Browse volume:

Key word:Product Application丨Application of microcapsules in spray drying!

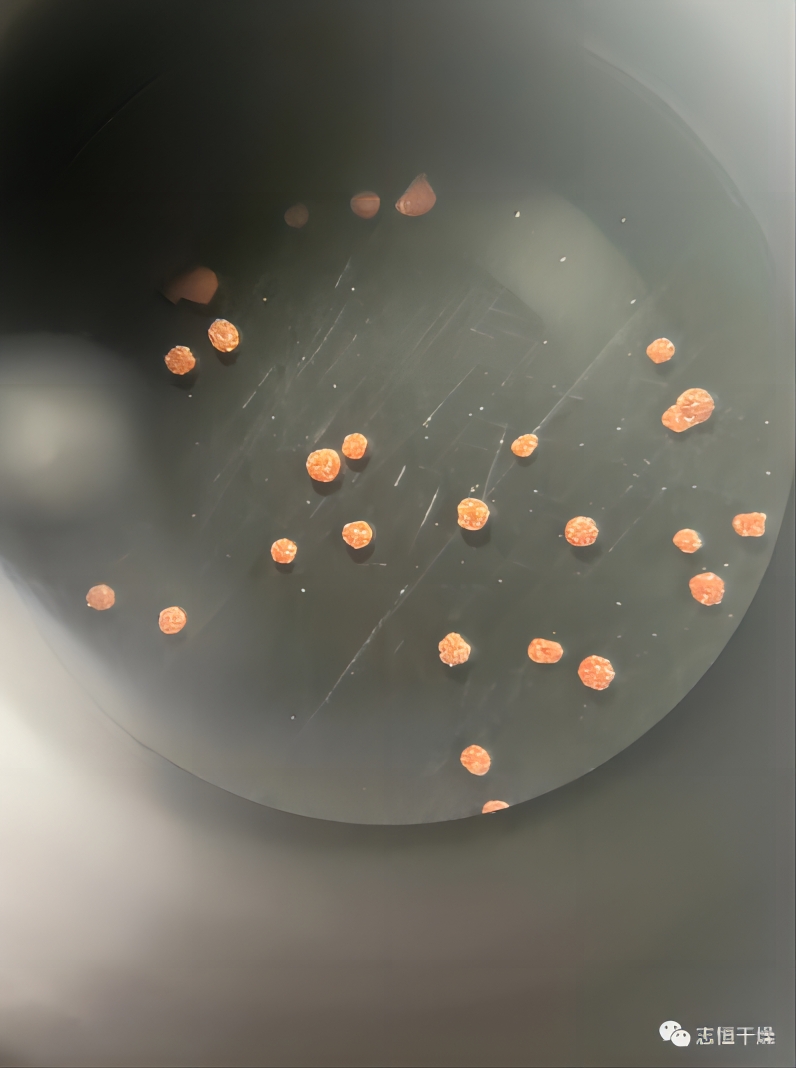

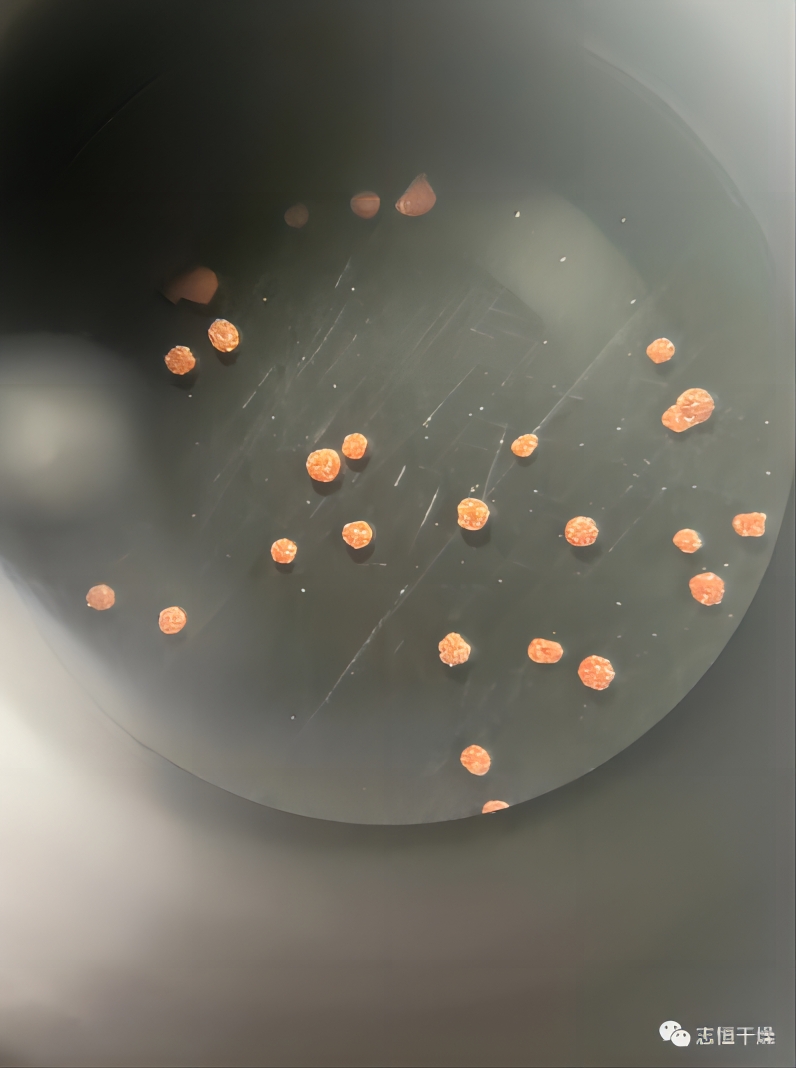

Microcapsules are a type of microcapsule technology that uses natural or synthetic polymer materials as wall materials to encapsulate liquids, solids or gases to form a semi-permeable or sealed capsule membrane.

Microcapsule technology

Microencapsulation technology uses the embedded material as the core material and the outer polymer as the wall shell of the microcontainer or packaging body. The size of the microcapsule is 5 to 200μm, and the thickness of the capsule wall is generally between 0.2μm and several microns. Under specific conditions, the components embedded in the capsule wall can be released at a controlled rate. In microencapsulation technology, according to the requirements of different core materials, the appropriate wall material is selected to achieve the functions of changing the physical state, volume and mass, controlling the release and reducing the volatility of the substance, isolating the active ingredients and protecting sensitive substances. Therefore, different microcapsule technologies can be selected according to the physical and chemical properties of the core material and the wall material and the expected application of the microcapsule.

Application technology of microcapsules in the food industry

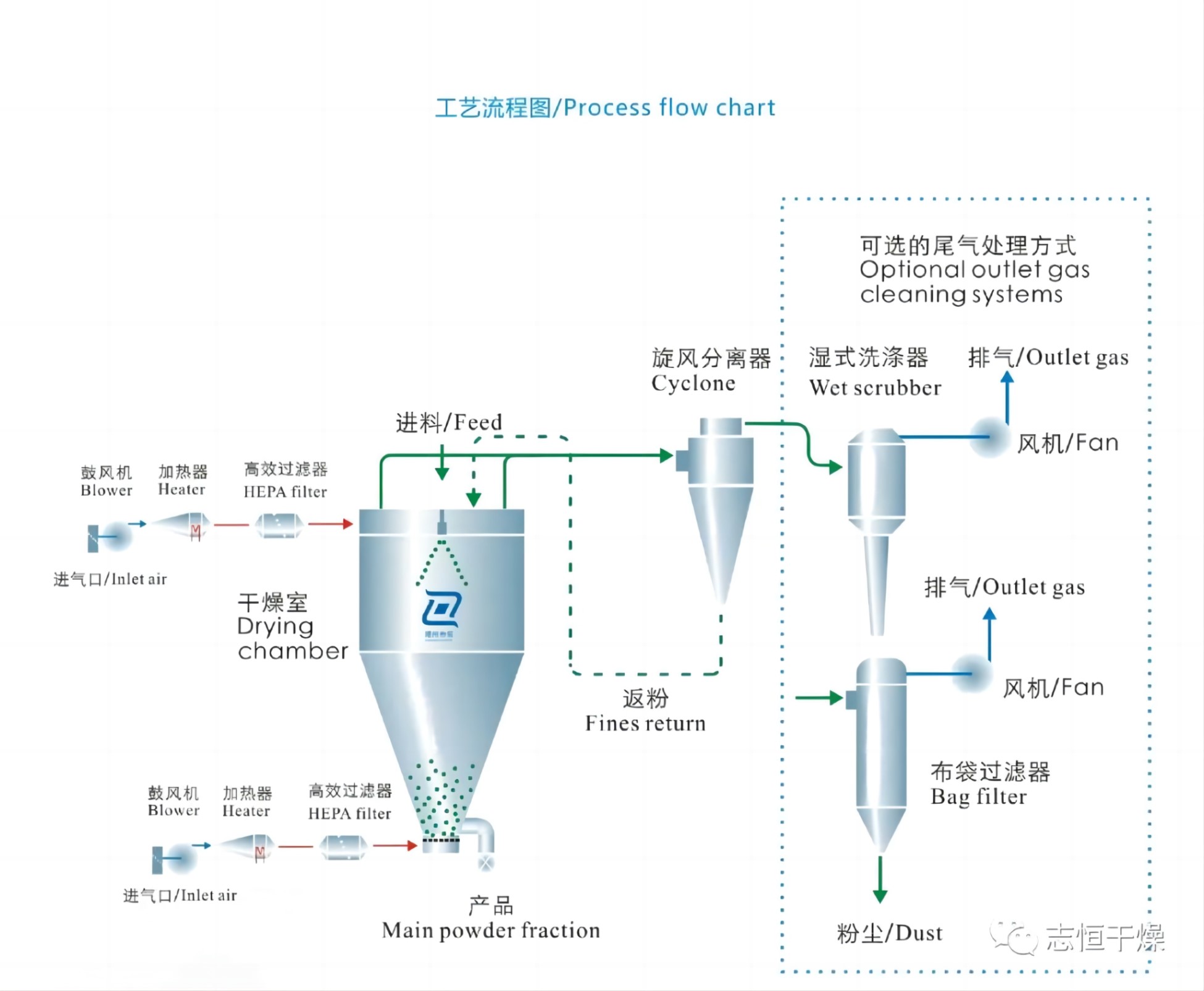

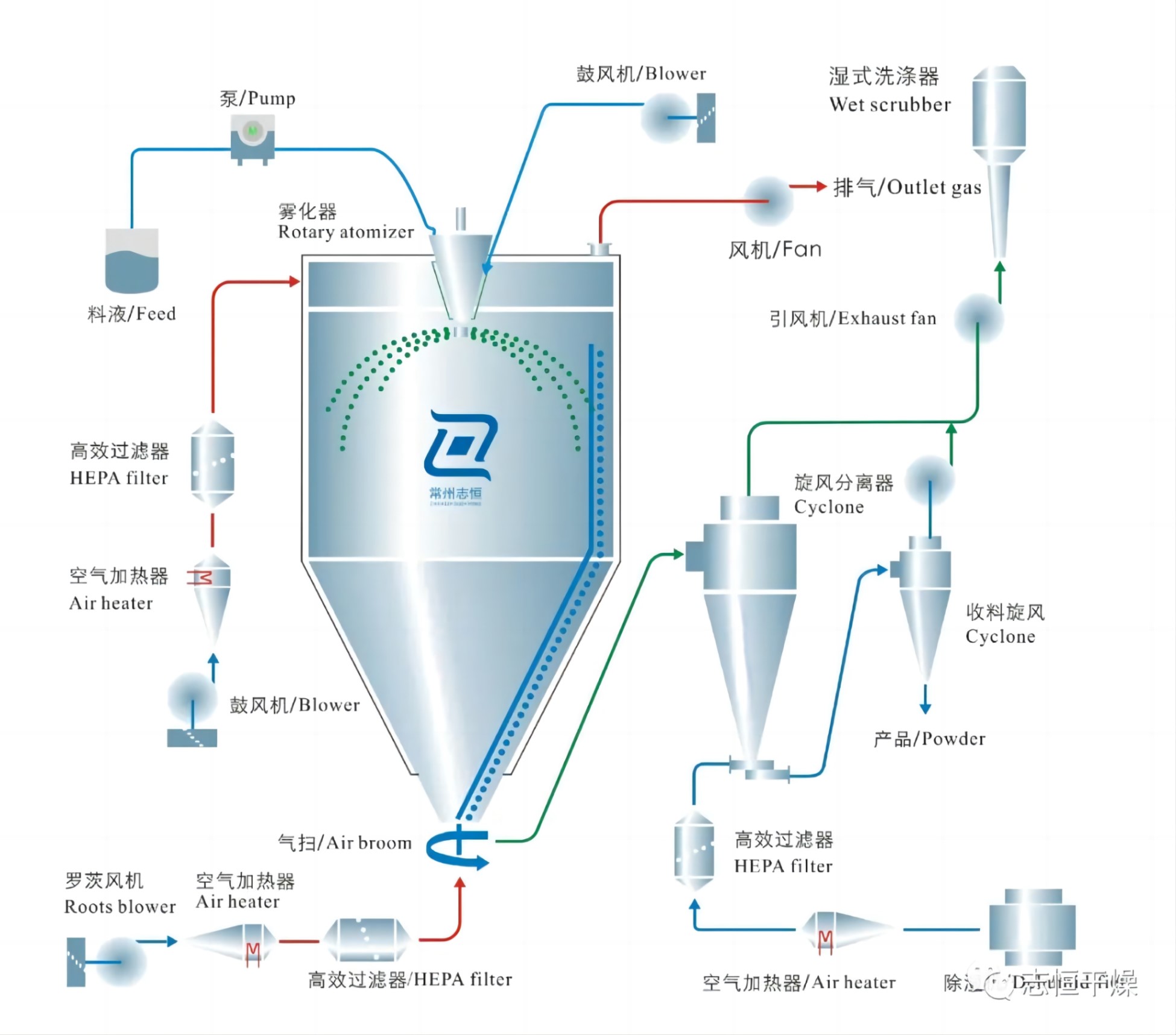

In recent years, microcapsule technology has been widely used in food industry production. Since this technology can change the form of matter, protect sensitive ingredients, isolate active substances, reduce volatility, mix incompatible ingredients and reduce the toxicity of certain chemical additives, it has shown good prospects for the development of high-tech in the food industry. At present, most domestic microcapsule manufacturers use traditional spray dryers. The drying of microcapsule droplets is first determined by the outlet temperature of the spray dryer and the solvent vapor content in the spray dryer exhaust. A higher outlet temperature of the spray dryer or a lower solvent vapor content in the spray dryer exhaust will affect the drying of the product.

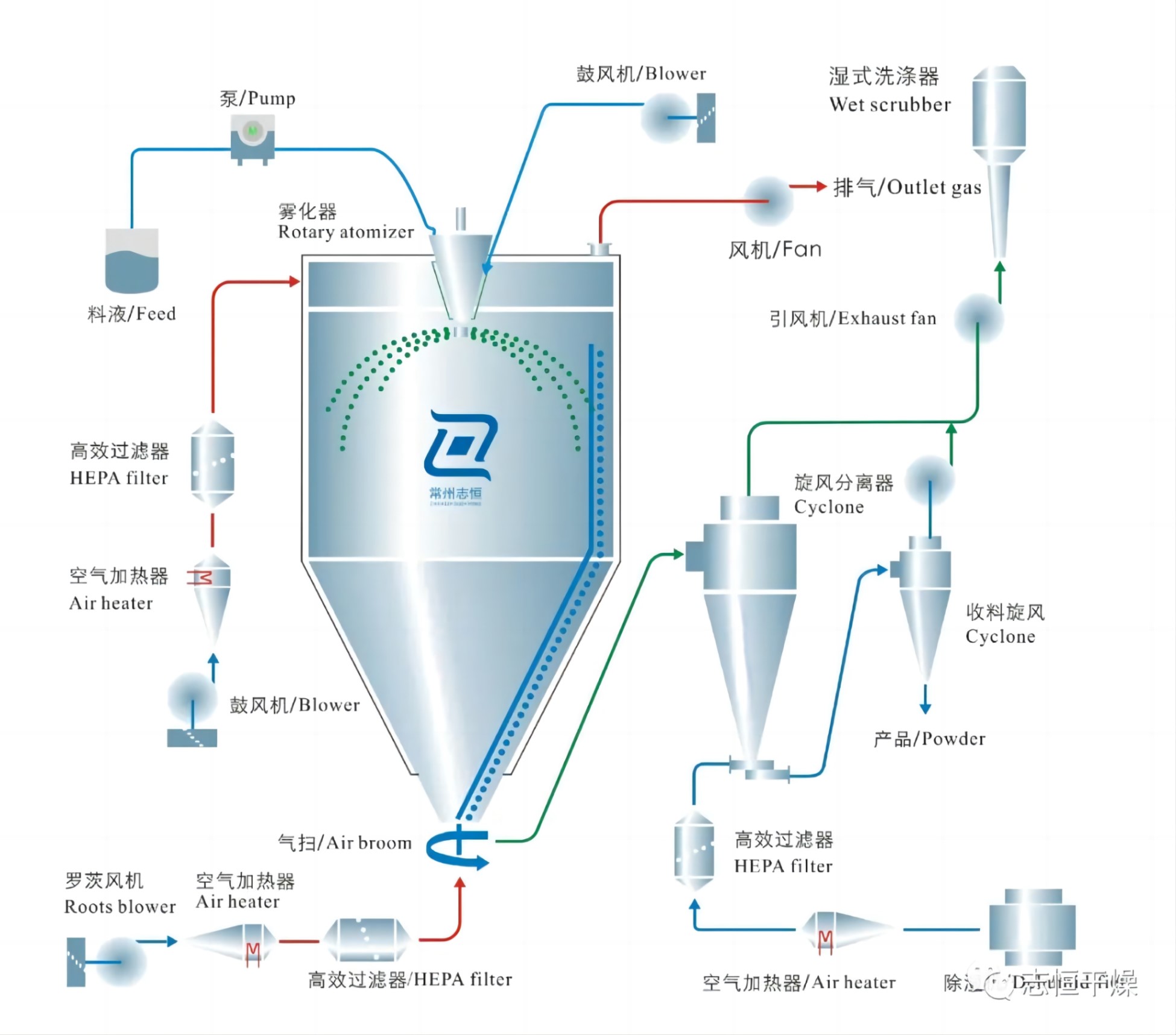

In response to the problems of microcapsules in traditional drying processes, Zhiheng has developed a new spray dryer that has been improved and developed for the food industry. It is a new spray dryer that is specially developed for materials with strong heat sensitivity, poor drying properties, low softening points, and strong hygroscopicity. As a more ideal new choice for solvent vapor content drying production. The inner wall and the top of the drying chamber are designed in the form of an air cooling jacket, which can reduce the temperature of the inner wall and prevent the material from coking and deteriorating due to contact with the high-temperature wall surface; the air at all air inlet nodes of the equipment adopts H13 filtration grade, which meets GMP production requirements.

This spray dryer is widely used in the fields of food additives and Chinese medicine extracts.

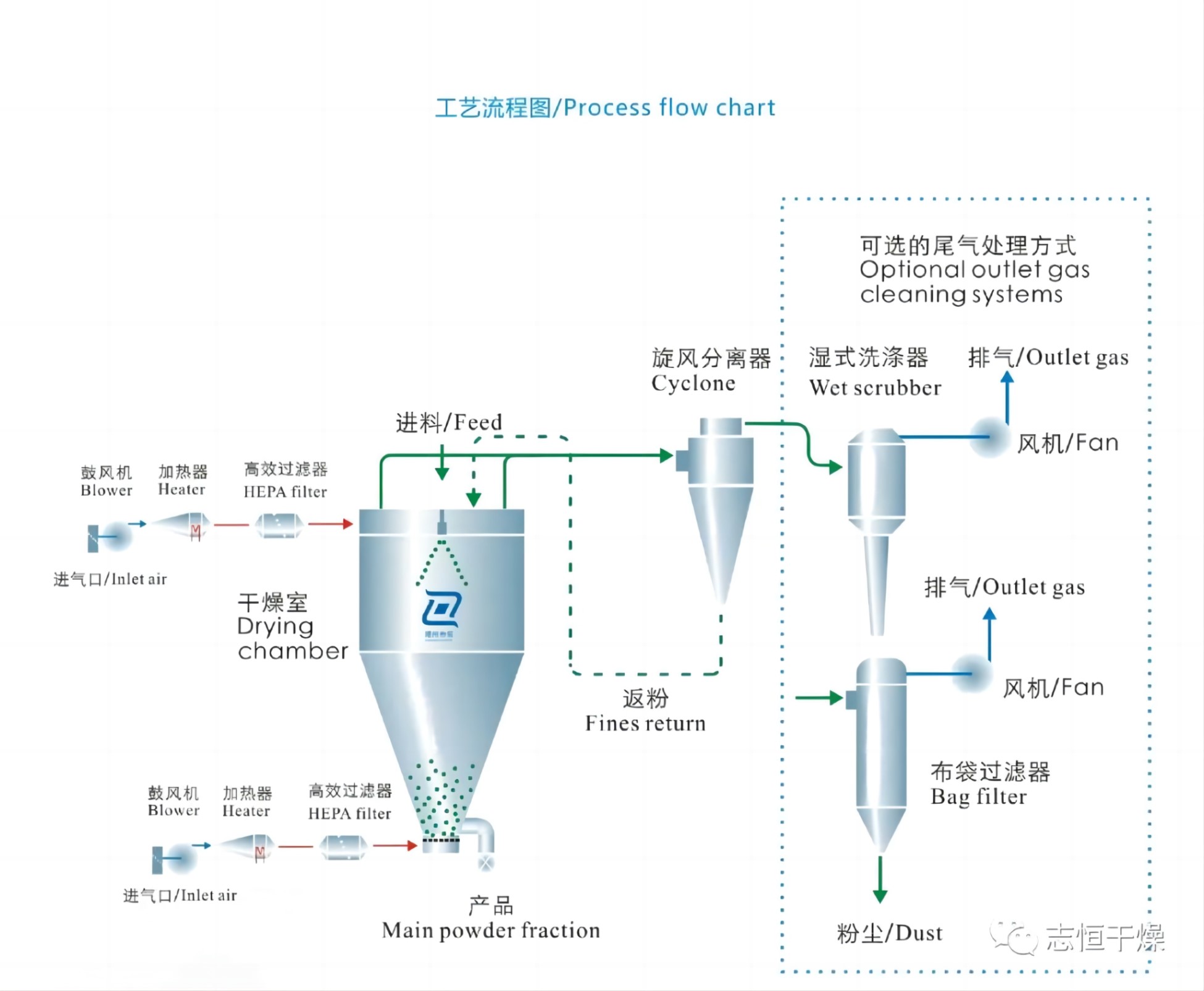

Food-specific spray dryer flow chart

The company has an internationally advanced experimental center, dedicated to combining the production process of customers' products with equipment manufacturing and processing, and industrial automation control, and providing customers with drying solutions suitable for their own production processes.