Industry Application丨Silicon-carbon negative electrode materials promote new energy development!

Information sources:本站 | Release date:

2023-11-03

| Browse volume:

Key word:Industry Application丨Silicon-carbon negative electrode materials promote new energy development!

Energy industry application technology -- Silicon-carbon negative electrode material

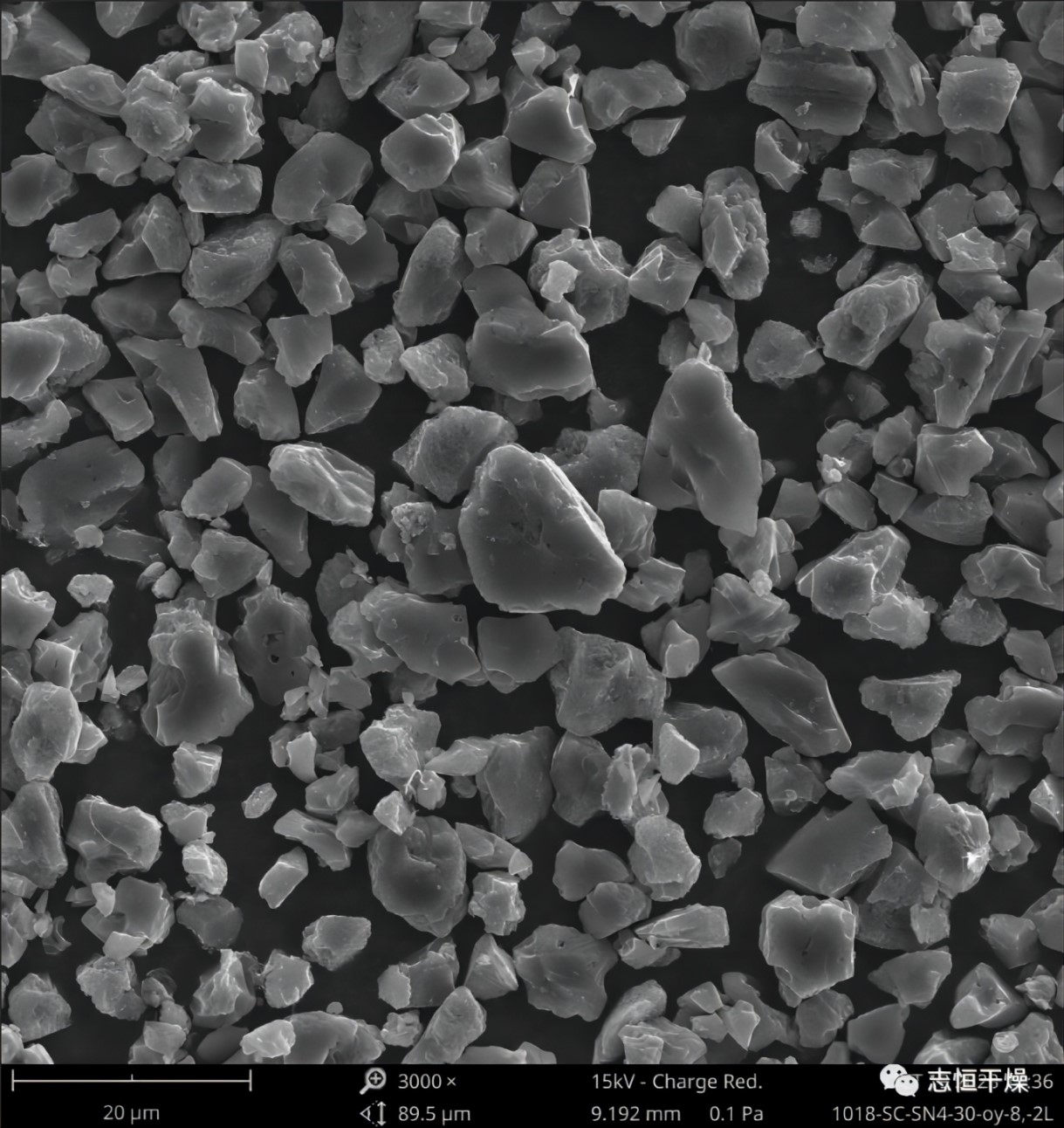

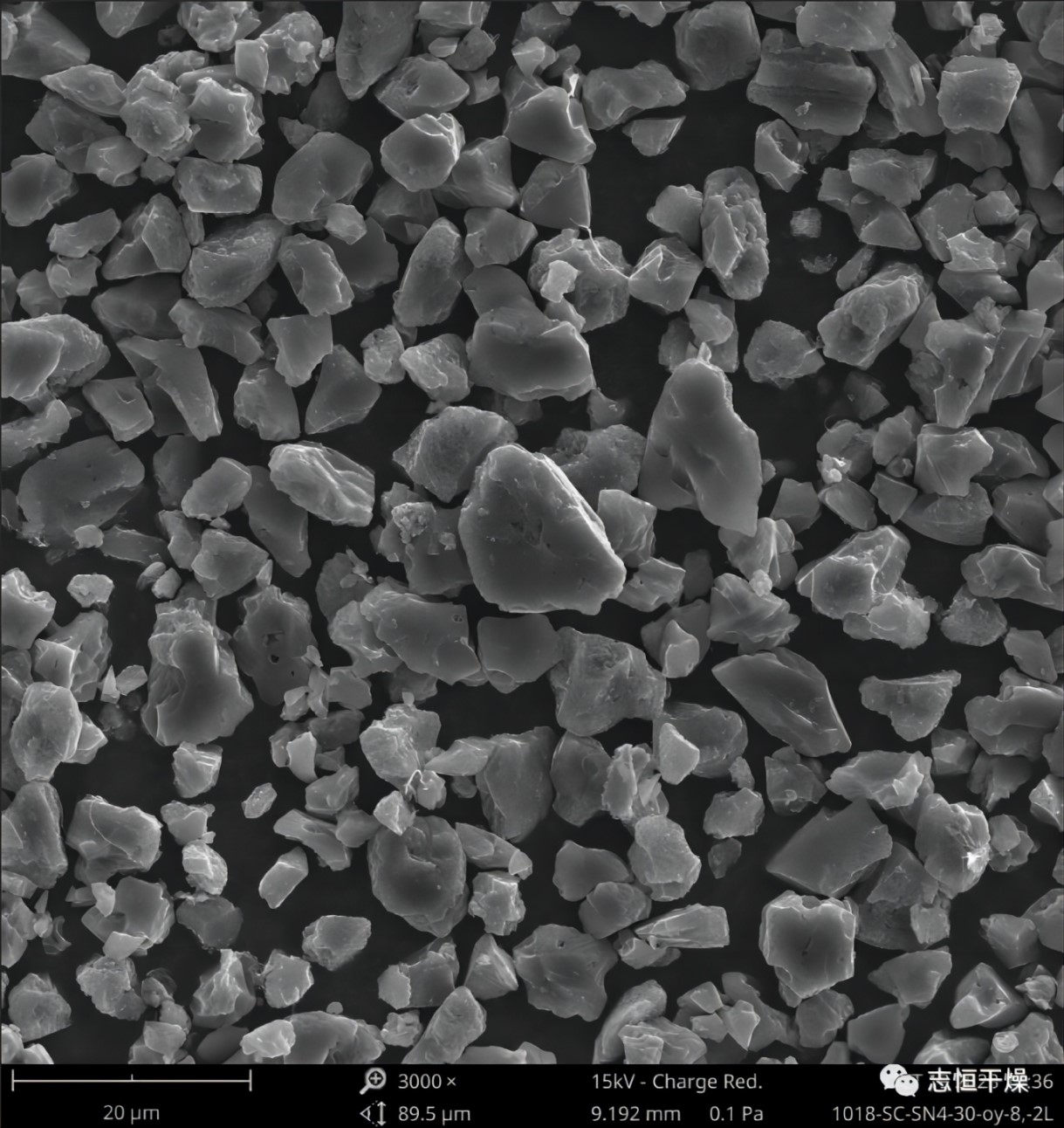

As we all know, continuously improving battery energy density is the unremitting direction of the lithium battery industry technology research and development institute. In the current lithium battery material system, negative electrode materials are mostly graphite materials (mainly artificial graphite and natural graphite). Compared with graphite negative electrode materials, silicon-carbon negative electrode materials have obvious energy density advantages. The theoretical energy density of graphite is 372mAh/g, while the theoretical energy density of silicon negative electrode exceeds 10 times, up to 4200mAh/g, which greatly improves the content of active substances in the battery and the capacity of the single battery cell. It has higher energy density and longer service life, high safety performance, good environmental protection and other characteristics. This is also an important reason why silicon-carbon negative electrode materials are increasingly concerned by the lithium battery field.

At present, most domestic silicon-carbon negative electrode material manufacturers use traditional vacuum rake dryers. However, the vacuum rake dryer used for silicon-carbon negative electrode materials has the following problems: the silicon-carbon negative electrode materials cannot be dispersed and the drying time is long; when the output increases, the required equipment volume is larger, the labor intensity of workers is high, and the materials need to be loaded and unloaded or turned over regularly, dust flies, the environmental pollution is serious, the thermal efficiency is low, generally around 60%, and the product quality is unstable.

Zhiheng proposes professional solutions to the problems

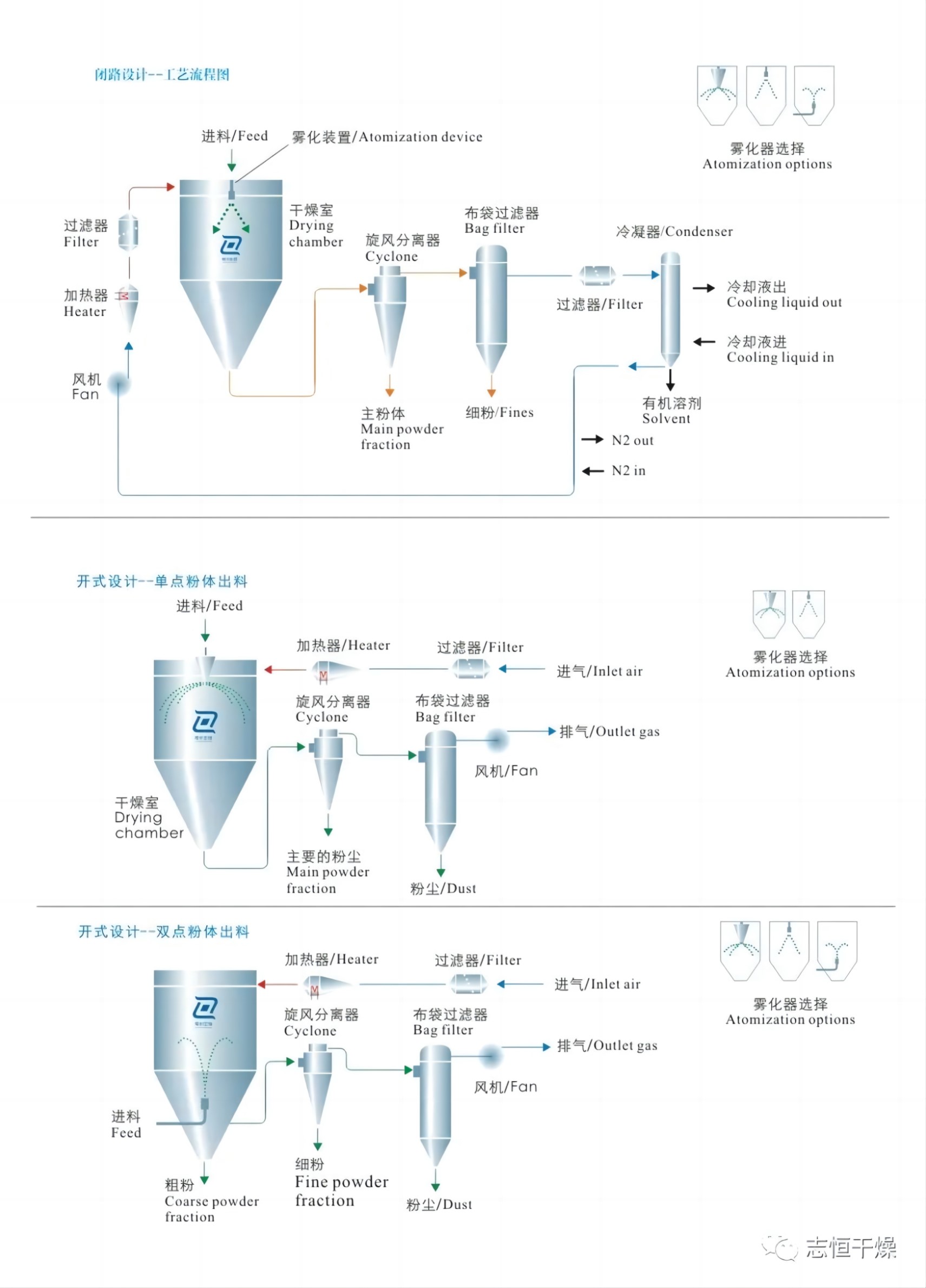

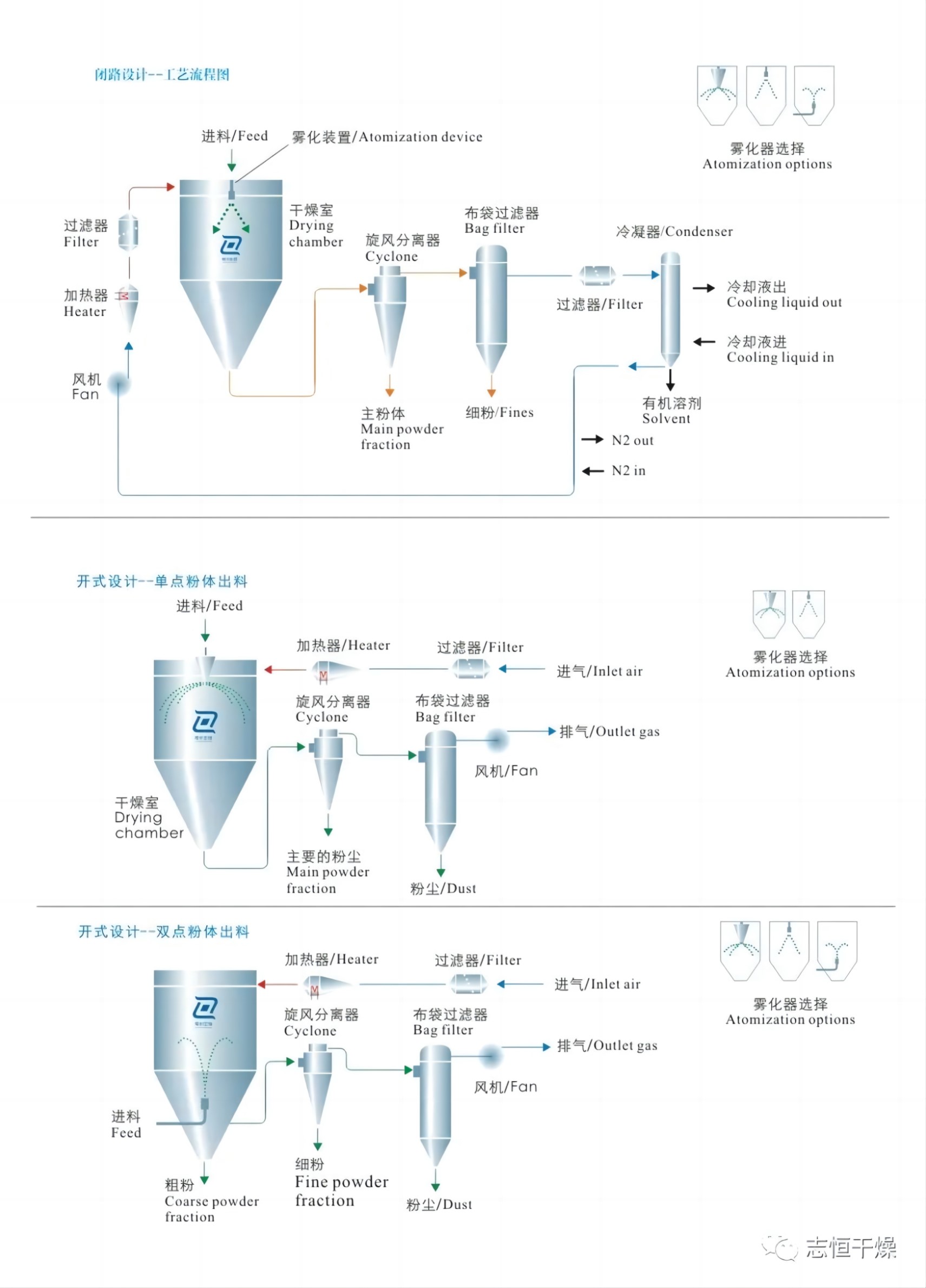

In response to the problems of silicon-carbon negative electrode materials in conventional drying processes, Zhiheng has developed a spray dryer for the new energy battery industry. In order to meet the special requirements of the new energy battery industry for powder properties, we have made some optimizations in atomization performance, system structure and configuration. It is an ideal new choice for drying liquid containing organic solvents. The equipment adopts a safer drying process. The new process can significantly reduce production costs, improve product quality, reduce workers' labor intensity, and is environmentally friendly.

It is widely used in products such as lithium (manganese) iron phosphate, silicon-carbon negative electrode, solid-state battery materials, sodium-ion battery materials, etc., and is well received by the new energy industry.

The vibration vacuum dryer is a vacuum heat conduction dryer that provides disturbance force for powder or particles through high-frequency excitation force. It has the characteristics of fast heat exchange frequency and high heat transfer efficiency. Compared with traditional vacuum dryers, the drying time can be shortened by one third. It is particularly suitable for new energy material powder and crystal granules.

New energy special spray dryer--process flow chart

The company has an internationally advanced experimental center, dedicated to combining the production process of customers' products with equipment manufacturing and processing, and industrial automation control, and providing customers with drying solutions suitable for their own production processes.