Current location:HOME > NEWS > Company news

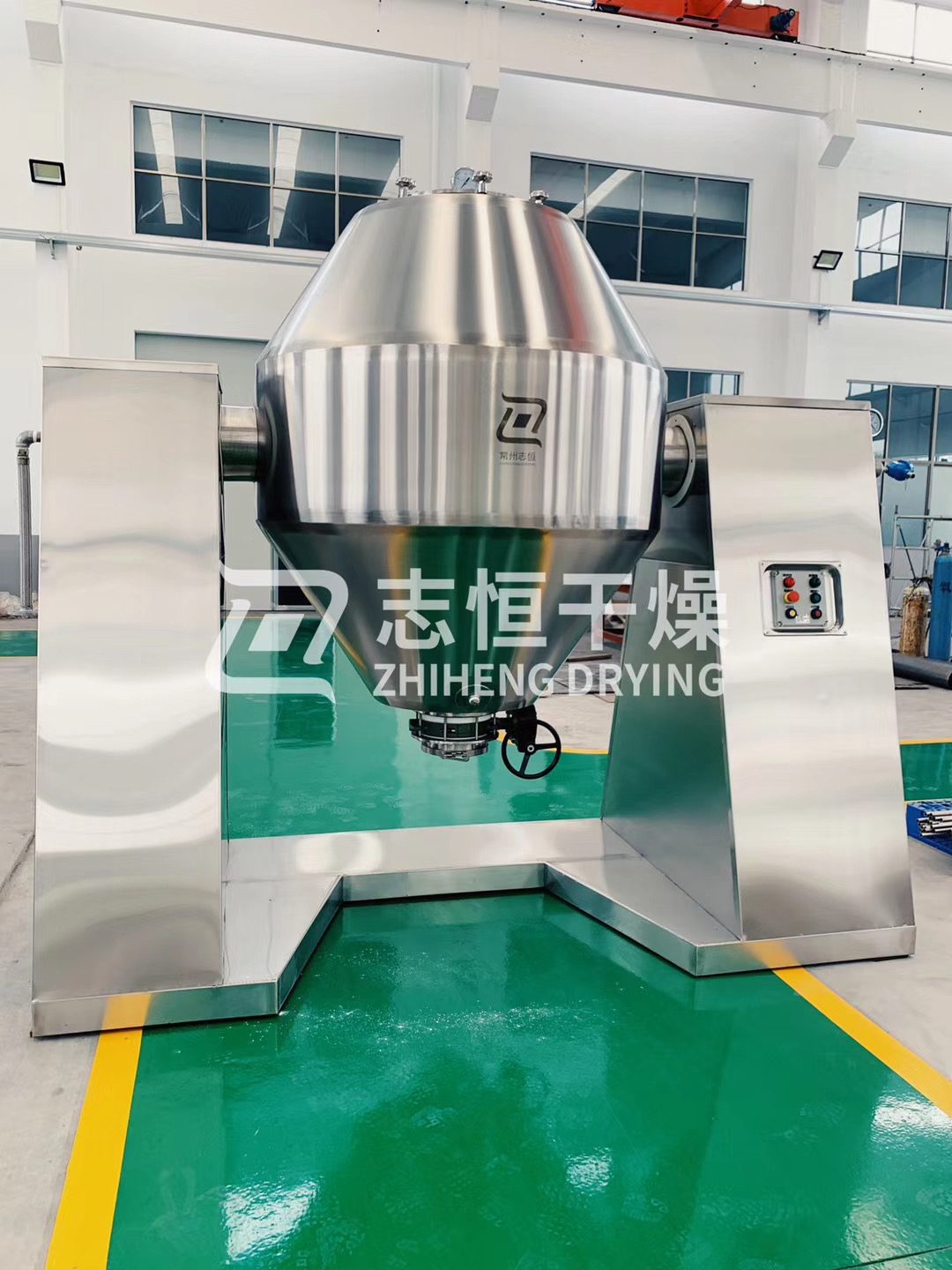

On June 15, 2020, another batch of double-cone rotary vacuum dryers was produced and processed by Changzhou Zhiheng Drying Equipment Co., Ltd. and shipped to a pharmaceutical raw material manufacturer in Shandong. The equipment shipped this time included 2 500L enameled vacuum rotary dryers, 1 1000L enameled rotary vacuum dryer, one 1000L 316L stainless steel rotary vacuum dryer and one 2000L 316L enameled rotary dryer.

This batch of equipment all adopts spinning production technology, mirror polishing technology, and boring machine processing technology. The working principle is that the material rolls by its own weight during the drying process. Compared with static drying, the production efficiency is high. The heat source can be selected from hot water, steam, and hot oil.

Features of Zhiheng Double Cone:

1. The inner liner spinning process makes the transition between the cone and the straight section smoother to avoid material accumulation

2. The specially designed hot water circulation system in the cylinder can greatly improve the heating efficiency of the double cone and shorten the drying time

3. The left and right support walls are processed by the overall boring machine to ensure the rotation concentricity of the cylinder, with an error of ≤10 wires

4. The inner cylinder is mirror polished, with a roughness of ≤0.4 microns and a smooth surface, which meets GMP requirements

5. The outer surface is finely matte treated, smooth and symmetrical, meeting human visual standards

Our company has strong technical force and pays attention to product production details. Customer satisfaction is the driving force of our development. Zhiheng Drying sincerely welcomes friends from all walks of life to visit us!