Current location:HOME > NEWS > Company news

The equipment adopts a closed circulation system and uses inert gas nitrogen as the transmission medium for heat and moisture, which greatly improves the safety of production.

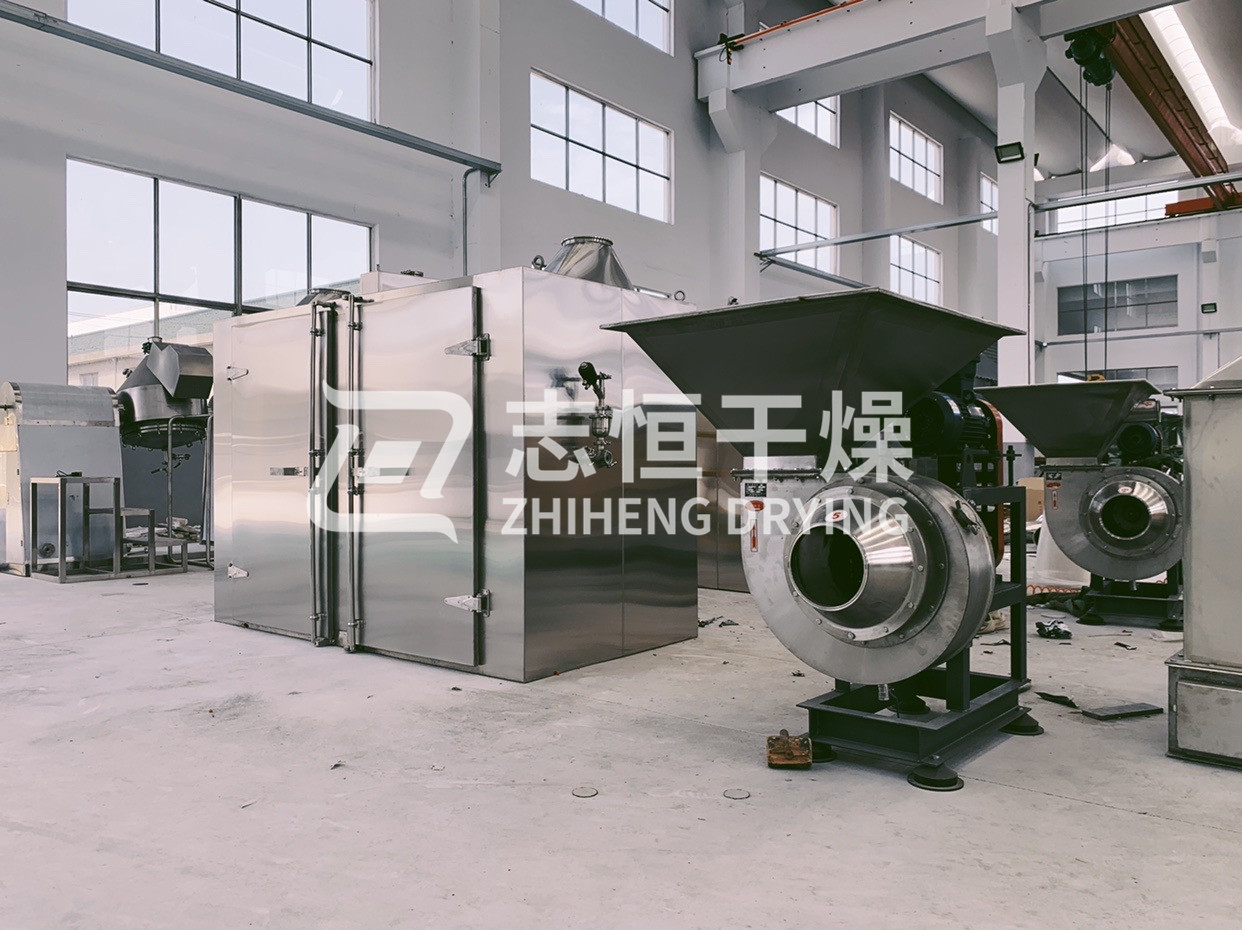

The closed hot air circulation oven system produced by Zhiheng Drying is mainly composed of a heating system, a drying host, a condensation system, a filtering and dust removal system, a hot air circulation system and an electronic control system. Different from traditional hot air circulation ovens at home and abroad, Zhiheng's closed hot air circulation oven has made many humanized improvements in structure and details.

1. The unique hot air distribution plate design is more evenly distributed in the box than the traditional louver structure, and it is easier to clean.

2. The internal circulation system is changed to an external circulation system, which effectively avoids cross-contamination between materials. There is no air duct inside the box, no powder residue, smooth and no dead corners, which truly meets FDA standards.

3. Zhiheng's engineers have fully absorbed foreign advanced technology and designed a no-dead-angle drying car, which completely solved the problem of residual powder on the drying car, helping many original pharmaceutical factories to greatly save production costs and increase production capacity.

4. The system uses a fully enclosed circulation fan developed by Zhiheng Drying, which has zero leakage and can be absolutely safe and reliable.

5. The electrical system designed by Zhiheng Electrical Engineers adds the last safety barrier to the equipment, making the system more perfect.

This time, Zhiheng is connected with a well-known domestic fluorine chemical company, which has a high industry status in the fields of global pharmaceuticals, electronic chemicals, fine and special chemicals. This cooperation has further deepened Zhiheng's understanding of the fluorine chemical industry and is a deep recognition of Zhiheng's drying technology strength.